Added on Wed 14 June 2017

Shrink sleeves: more than just labels

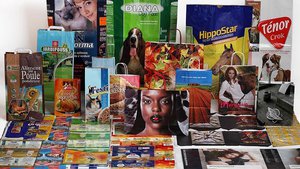

Flexible labels, also known as shrink sleeves, allow a creative and revolutionary packaging of bottles, perfumes, cosmetics, drugs and many other products. Since the 70’s this printing substrate vastly changed the way of packaging. It is not only about the aesthetic appeal of shrink sleeves, but also their ability to protect and promote products.

Shrink-sleeve technology

Shrink sleeves are made with a heat-shrinkable material (heat-sensitive). They can be produced in any shapes and lengths, so are adaptable to all types of container.

After printing, these film sleeves are wrapped around their containers (bottles or flexible containers) and fixed through a heat-shrinking process.

Printing on shrink sleeves

The most effective and fastest way to print on shrink sleeves is flexo printing, which uses digital photopolymer or rubber plates with water-based, solvent-based or UV inks. The printing forms are inked by a roller called “anilox”, the surface of which is engraved with very fine cells that transfers the correct amount of ink onto the plate, which then transfers the ink onto the shrink sleeve.

Plates for shrink-sleeve printing

The pre-press process to print this kind of labels requires precise technologies and professional abilities. On the Italian scene, Nu-Maber provides the greatest expertise in this field.

Subscribe to our NEWSLETTER and stay updated on the lastest Nu-Maber news

You may also be interested in:

Quality certification ISO 9001 for Nu-Maber

ISO 9001 quality certification, a standard reference for the quality management system

Kodak Flexcel NX: Nu-Maber, your new certified partner

Kodak Flexcel NX: certification of a high quality standard for Nu-Maber

Flexible packaging: free to choose with flexo printing

Flexible packaging is employed to contain many types of products

Nu-Maber

Products and solutions for Flexo

Via Giorgione, 6 – 31056 Roncade (TV)

Tel. (+39) 0422-1650009

Nu-Maber Products and solutions for Flexo – Registered offices: Via Giorgione, 6 – 31056 Roncade (TV) – P.IVA 00836770263 – REA Treviso 00836770263 – Cap. Soc. €99.000 – Privacy