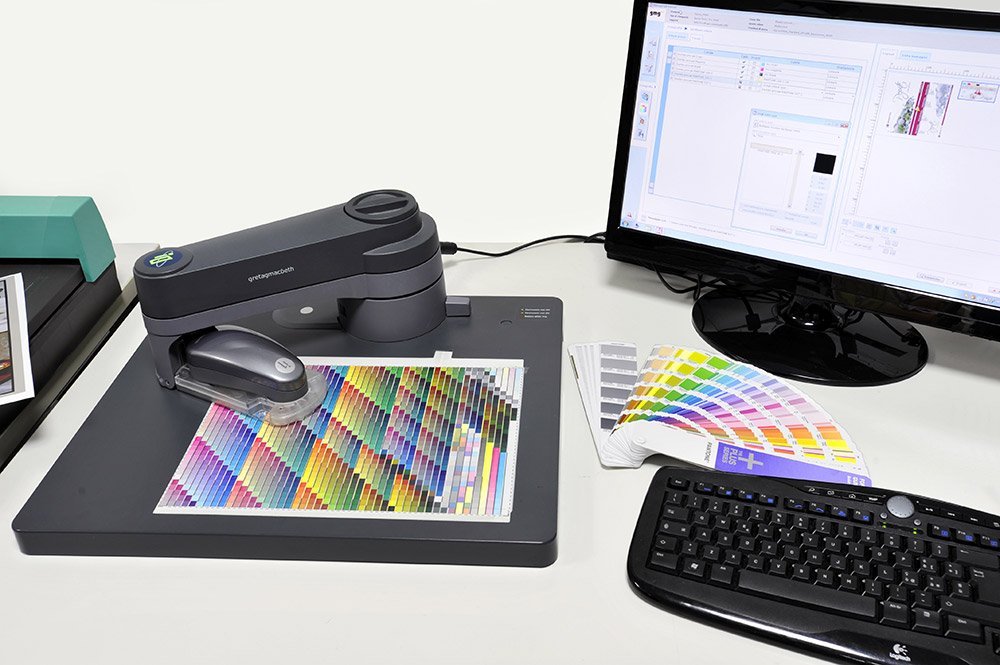

Our graphic studio

The graphic studio is the soul of our company, with 30 workstations, a professional and fast service for print buyers and flexo printers.

In our graphic studio artworks supplied by Customers including logos and images are optimised for flexo printing.

The 30 workstations are equipped with professional software for flexo pre-press (Esko ArtPro and HYBRID PACKZ) and with the commonest image editing software (Adobe Illustrator, Photoshop, InDesign, etc.).

In our studio we also print certified colour proofs on paper and on clear film simulating dot patterns for customer approval. Large-format colour prints can be also supplied.

Flexo printing forms in Veneto

Nu-Maber is a well-known and professionally reliable company based in the area of Treviso for flexo plate making.

For plate making, Nu-Maber is equipped with: four Esko CDI imagers for digital plates up to the maximum format size (132×203 cm), also with a HD resolution of 4000 dpi, one automated plotter to cut the plates and two independent lines for plates exposure, development, drying and finishing. Nu-Maber’s graphic studio has 30 workstations equipped with software designed for both flexo and the certified colour proofing.

Printing forms in flexo

Today, flexographic printing (flexo) is one of the most used printing technologies. It is efficient and flexible for printing packaging, shrink labels, adhesive tape, gift wraps, table covers, school books, trays, paper and plastic bags and lots more besides.

Flexo printing forms make printing possible on a nearly unlimited range of substrates: not only paper but also aluminium, plastic, undulated carton, film and other materials.

Unlike traditional printing, flexo printing forms can be produced in digital photopolymer or rubber. The printing forms are then inked by a roller called “anilox”, the surface of which is engraved with very fine cells that transfer ink onto the plate.

Flexo plates for perfect printing

Plate making is the process of producing plates that will be used to transfer the artwork by printing onto paper or other materials.

Flawless plate making is the first, essential step to achieve optimum print results. Any mistake in the design process can cause more or less visible defects on the printed material, resulting in additional print runs, loss of time on press, and additional costs.

Nu-Maber

Products and solutions for Flexo

Via Giorgione, 6 – 31056 Roncade (TV)

Tel. (+39) 0422-1650009

Nu-Maber Products and solutions for Flexo – Registered offices: Via Giorgione, 6 – 31056 Roncade (TV) – P.IVA 00836770263 – REA Treviso 00836770263 – Cap. Soc. €99.000 – Privacy