Kodak Flexcel NX: certification of a high quality standard for Nu-Maber

Kodak Flexcel NX: Nu-Maber, your new certified partner

Kodak Flexcel NX: certification of a high quality standard for Nu-Maber

The Kodak Flexcel NX technology is an acknowledged standard in the flexo market granting efficient printing and reducing ink and material waste. The Kodak plates processed with the Flexcel NX system enable to achieve printed density values up to 30% higher than traditional plates. This can also help reduce the number of plates and colours for each project. This system allows a quicker change of plates on the printing press and a significant reduction of the total costs by granting a high print quality and by making the whole flexo process more efficient.

Efficiency, consistency and quality guaranteed by Kodak Flexcel NX

Becoming a certified Kodak partner, Nu-Maber proves once again that they can grant strict premium standards, consistency in production quality and precise 1:1 reproduction of the dots on the plate. Like it’s confirmed by the major media centers. Such criteria are essential to achieve the certification and are confirmed by a rigorous analysis of TIL and processed plates submitted to the Kodak Technology Center.

More about the process of the Kodak Flexcel NX plates

Before UV-exposure and imaging, a Kodak TIL sheet is laminated to a Flexcel NX plate. This stage is extremely important for:

- removing the presence of oxygen,

- allowing the creation of wide-gamut flat top dots with a 1:1 reproduction that matches the original digital file,

- granting stable and consistent density values on the plate as well as in printing.

High resolution exposure for a perfect plate

The high resolution exposure of the Kodak TIL sheet results in a negative mask that is laminated to a Flexcel NX plate inside the Kodak Flexcel NX Laminator unit. This is a critical step for:

- creating a close contact between the sharp contour lines imaged on the mask and the photopolymer layer,

- improving repeatability of the process,

- the laminated TIL sheet protects the plate surface from the air and prevents oxygen to interfere with a correct imaging of the design.

For more information on our services, and for a no-obligation price estimate CONTACT US NOW!

Subscribe to our NEWSLETTER and stay updated on the lastest Nu-Maber news

You may also be interested in:

Quality certification ISO 9001 for Nu-Maber

ISO 9001 quality certification, a standard reference for the quality management system

Kodak Flexcel NX: Nu-Maber, your new certified partner

Kodak Flexcel NX: certification of a high quality standard for Nu-Maber

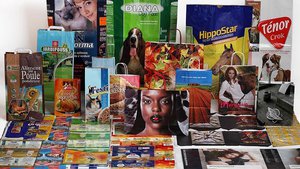

Flexible packaging: free to choose with flexo printing

Flexible packaging is employed to contain many types of products

Nu-Maber

Products and solutions for Flexo

Via Giorgione, 6 – 31056 Roncade (TV)

Tel. (+39) 0422-1650009

Nu-Maber Products and solutions for Flexo – Registered offices: Via Giorgione, 6 – 31056 Roncade (TV) – P.IVA 00836770263 – REA Treviso 00836770263 – Cap. Soc. €99.000 – Privacy